Optimized design of industrial motor control systems has a direct impact on power efficiency, which in turn has a huge impact on global electric power consumption. In fact, the International Energy Agency (IEA) estimates that systems driven by electric motors account for more than 40% of global electricity consumption.

The IEA also estimates that a 10-15% improvement in electric motor-driven system efficiency could reduce total global electricity use by 5%. This highlights a significant opportunity for the industry to make a real difference in energy consumption.

The Importance of Industrial Motors

As we automate more industrial processes in a bid to achieve efficiency and repeatability, electric motors are found in almost every sector with power ratings from a few Watts to tens of kilowatts.

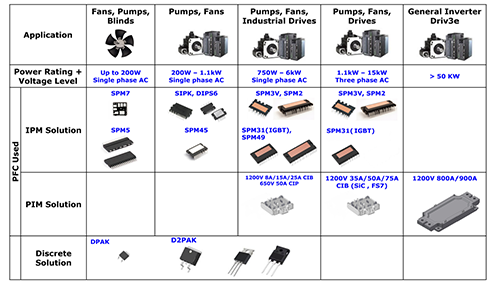

The industrial sector tends to have some of the largest and most powerful motors in use, and they consume the most power. Key application sectors are for fans, pumps, and industrial drives and while these are probably the most common, there are many more use cases.

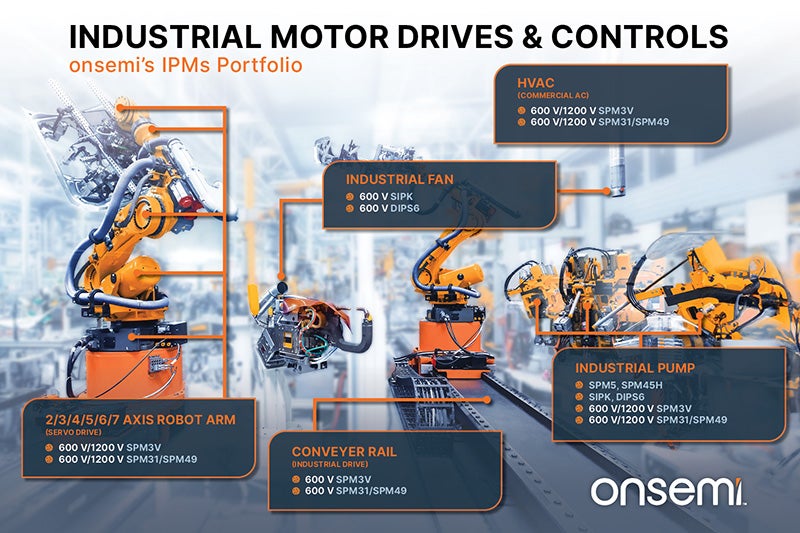

Robotics as a sector is wholly reliant on motors to move the ‘arms’ of the robots as well as driving the wheels of mobile robots such as automated guided vehicles (AGVs), delivery robots, and the like. In materials handling, electric motors are used in cranes and to drive the belts of conveyors, both indoors and outdoors.

Electric motor-powered winches are used in industrial applications and are also found across marine, agriculture and automotive. Electric motors are deployed in building automation to power elevators and moving walkways as well as opening and shutting windows and doors, among dozens of other use cases.

This shortlist barely scratches the surface and, as we strive to reduce pollution, many applications that use small internal combustion engines will soon be powered by electric motors.

The Role of Power Modules in Efficient Designs

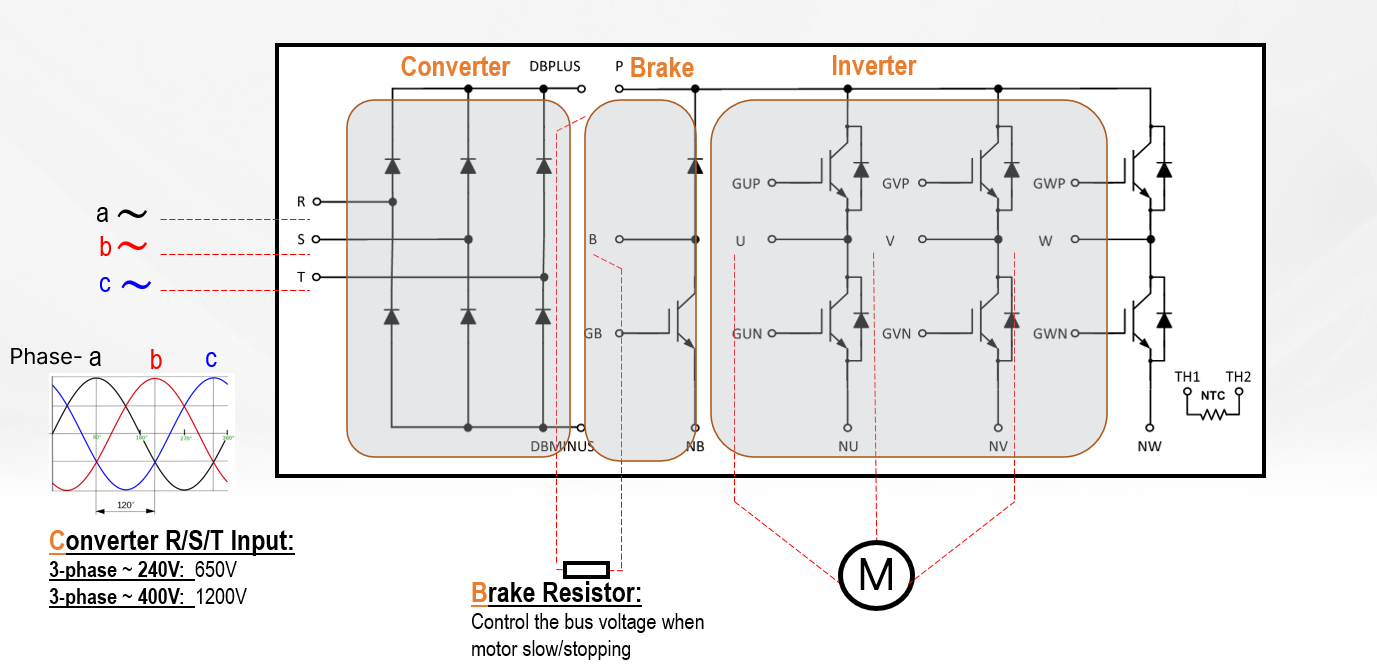

While single-speed motors can simply be connected to a power source, usually the mains, variable-speed motors require some form of electronic speed control to operate. Often this will be a system consisting of a converter, a brake, and a three-phase inverter with the switches such as silicon MOSFETs or SiC MOSFETs, IGBTs, or even GaN HEMTs.

During normal operation, the inverter supplies power to accelerate the motor and when slowing (especially with high inertia loads) the brake section and external resistor dissipate the regenerative energy.

When designing a motor control circuit, designers have several goals to achieve including efficiency, reliability, robustness, compact size, and thermal performance. In most cases, this involves trade-offs to reach an acceptable solution.

While designs can be constructed entirely from discrete components, there are many benefits to using a pre-configured modular design with a motor controller circuit.

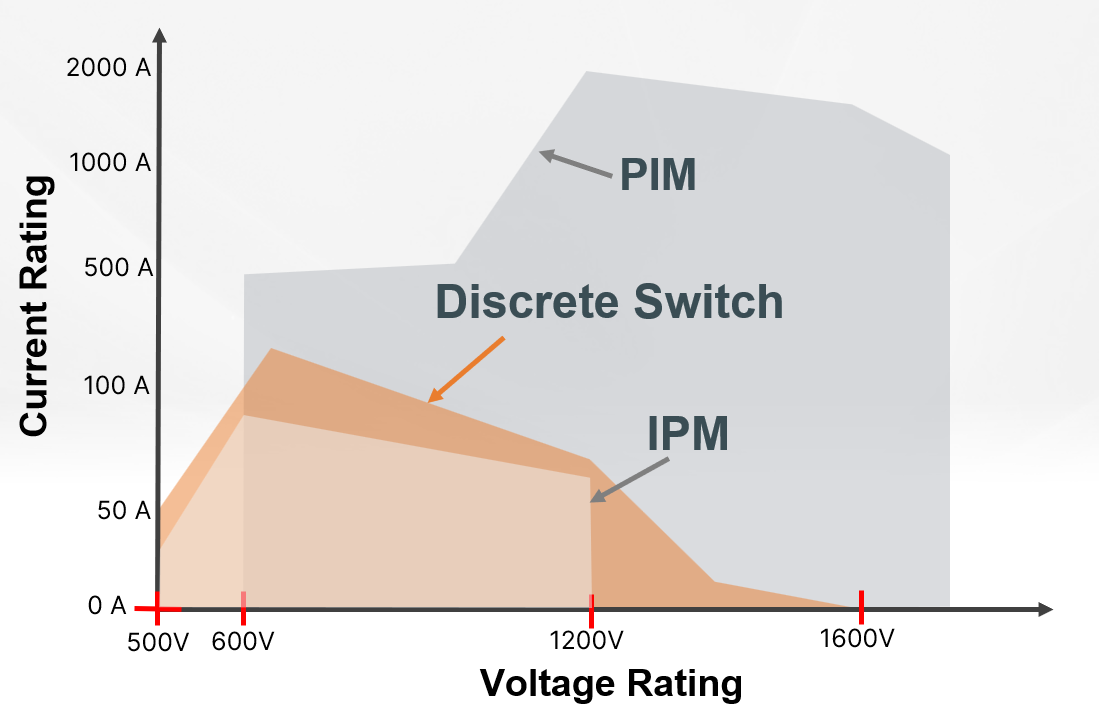

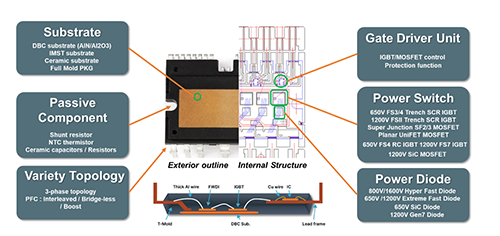

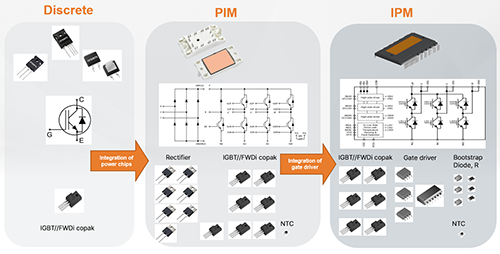

An intelligent power module (IPM) is an all−in−one technology that integrates the PFC components into a compact package. onsemi IPMs contain all required passive components, gate drivers, power switches, and power diodes. They are arranged so different topologies may be implemented for different applications.

IPMs include the gate driver while power integrated modules (PIMs) do not. In high-power applications the gate driver can introduce noise, so in these applications it is fitted externally on the main PCB to avoid this issue.

To enhance efficiency in high-frequency motor applications, designers often turn to silicon carbide (SiC) technology. SiC delivers higher electron mobility, lower intrinsic carrier concentration, and higher thermal conductivity. SiC MOSFETs offer higher current densities, lower switching losses, high-temperature operation, and the ability to operate at higher frequencies. This results in more efficient operation, less cooling, and smaller passive components – all of which lead to a more compact solution.

onsemi Solutions

As different applications have their own performance and cost goals, onsemi offers a wide portfolio of IPMs and PIMs based on both IGBT and SiC technology. If higher efficiency, smaller size, and/or higher frequency are required, then SiC is the technology of choice. If ease of control and/or cost is most important, then IGBT will provide an ideal solution. The latest 1200 V Field Stop 7 (FS7) IGBT is featured with robustness, high power

density and low conduction loss. For example, the FGY100T120RWD can conduct 100 A in TO-247 discrete packaging with Vce(sat) as low as 1.4 V – one of the lowest in the market.

onsemi’s IPMs are suited to applications from a few Watts to 15 kW while the PIM range works in designs from a few hundred Watts to over 50 kW.

While, as an emerging technology, individual SiC components may cost slightly more than silicon equivalents, this is more than offset by system-level cost savings (including passives and cooling). Additionally, onsemi has an extensive and complete selection of auxiliary circuit components for SiC to complete designs.

Summary

Electric motors consume more energy than any other single application, around 40% of the world’s total consumption. Efficiency gains here will have a substantial impact on reducing global electricity use.

Modern designs using SiC-based modules offer high performance, ruggedness and small size, besides total system cost reduction.

onsemi is one of the market leaders in this technology area with a comprehensive range of modules and associated components. Learn more about how to increase power efficiency in industrial motor control in our white paper. Check out our new industrial motor drive system solution guide.